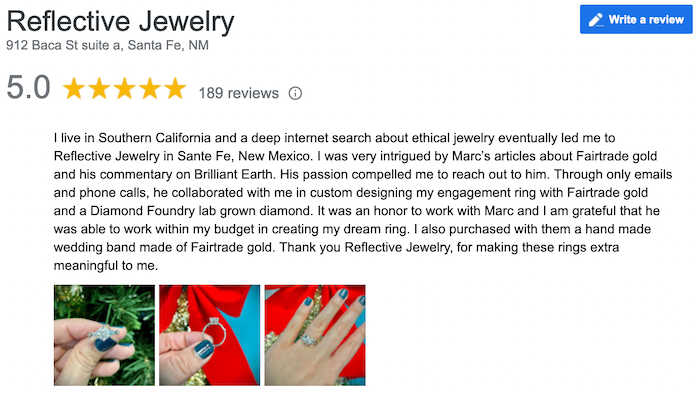

We use both 24K Fairtrade Gold and recycled gold to make our designs with our own hands and tools.

SPECIAL NOTE: HANDMADE GOLD WEDDING RINGS MADE USING REPURPOSED GOLD FROM OLD JEWELRY OR FAIRTRADE GOLD IS OUR SPECIALTY! WE CAN MAKE ANY RING DESIGN YOU WANT, FROM A CLASSIC BAND TO PAVÉ OR ETERNITY RING DESIGNS!

Looking to work with an awesome small artisan studio with excellent cred? Call us at our shop at 888-733-5238 or email info (at) reflectivejewelry.com for a FREE, no-pressure consultation. —Marc Choyt, co-owner

These days, we are among the very few jewelers who have the ability to fabricate rings using old-world handmaking techiques. We actually make the majority of our Reflective Jewelry gold over silver and two tone gold rings entirely by hand.

Additionally, rings that are created from our customer's old gold and gems that do not require CAD/CAM drawings are also made in the same method illustrated below.

This means that the energy, love, and devotion to craft excellence that our jewelers have developed over decades is actually infused in the process of making the ring itself! You will be able to feel the difference — and, I'm sure — appreciate knowing that, even in the case of a classic comfort fit flat topped wedding band, each and every ring is going to be inherently unique.

We start with either your gold (from repurposed old jewelry) or our 24K gold. We make our own wire and sheet from which we then fabricate our rings — working on cottonwood stump benches, and using hand-forged anvils, hammers made of steel and cow horn, and a huge variety of tools we created ourselves.

This two-minute video below takes you into our workshop and shows you some of the tools and techniques we employ:

So, here's the bottom line:

If you order a classic wedding band, it will be made by one of our jewelers Santa Fe, NM — often using Southwestern fabrication techniques date back to the old-world style artisanal methods of the Spanish Conquistadors.

Below we’ve broken down this process into 11 steps. The end product is a gorgeous 4mm Flat Topped Classic Comfort Fit Wedding Band, pictured just below and available for sale here.

1. If we're making a ring from Fairtrade gold, we start with 24K Fairtrade Gold — which is formed into small grains. If we're making a ring from your material, we start out at Step 4: melting the gold to make an ingot.

2. The gold is weighed out in the amount needed for your ring:

3. The 24K (pure) gold is mixed with an alloy to create either 14K or 18K and a particular color — such as white gold or rose gold:

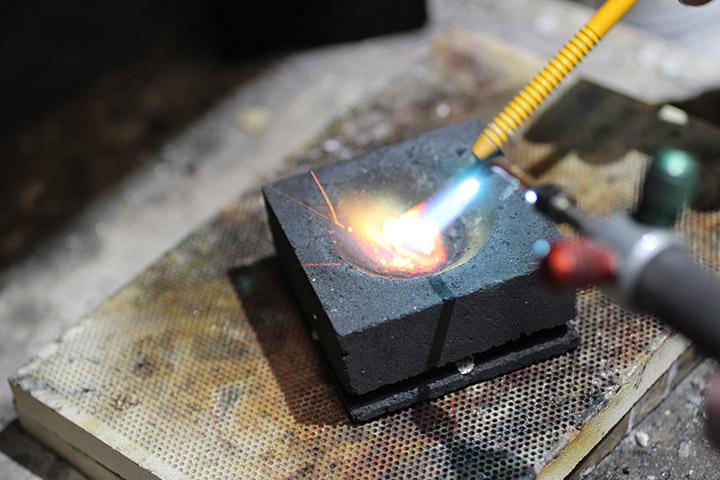

4. Gold and alloy are then melted down with a torch:

5. Now, we have a round gold nugget:

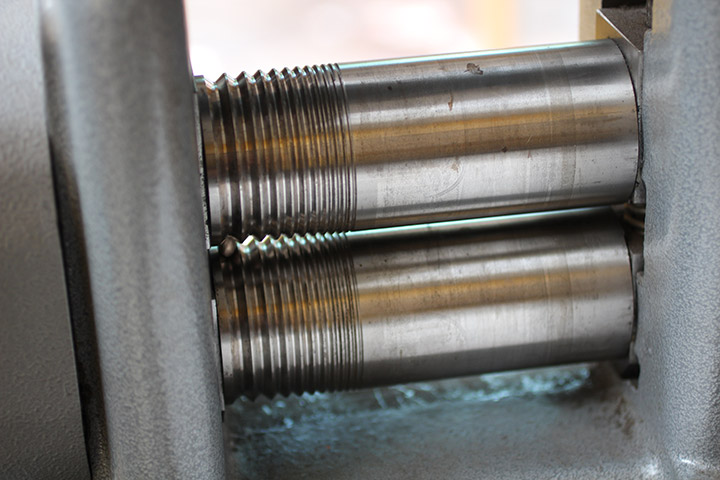

6. The next step is to roll out the nugget into a wire, using a rolling mill as shown:

7. Below is what the gold looks like after it's gone through the rolling mill. This process may look easy, but it's not — just ask our apprentice jeweler! It takes a lot of practice to make wire that is the exact right width and thickness for your ring.

If we are making a ring that is a combination of gold and silver (typically a gold design over a silver band), we go through the same process with the gold element of the ring. (FYI: with the silver elements, we purchase recycled silver to keep costs down.)

8. The wire is formed into a ring using hand tools:

9. The ring is shaped using a hammer and a mandrel. Though our jewelers make this look easy, again, it is not — particularly when we have to line up a complicated knot pattern so the joint is barely noticeable even when you look for it.

10. Next, we polish the gold ring on our polishing wheel. This step is where your ring becomes "comfort fit" — which essentially means that the underside of the ring is curved away from your ring, to reduce friction. We also can add a matte, hammered, or various other types of finishes on the surface of the ring:

11. And finally, this is what the ring looks like once it is off the wheel:

[Curious what else our jewelers can do? Discover our Custom Jewelry here!]

Next Steps for Your Handmade Repurposed Gold or Fairtrade Gold Wedding

With over 80 years of combined bench experience in old-world artisan techniques, our jewelers are capable of anything and everything. We'll even reuse your old or inherited gold and gems to make new jewelry out of old!

If you’re ready to order a handmade wedding ring, or have any questions, I'm here to help! Browse our website, stop by our gallery in Santa Fe NM, call 888-733-5238, or email me at info (at) ReflectiveJewelry.com. If what you really want is a custom gold ring, I’ll be happy to answer all your questions with absolutely no obligation. You can find more info here — but get in touch, and we can set up a phone or Zoom consultation.

Happy shopping!

Marc Choyt is president of Reflective Jewelry, a designer jewelry company founded in 1995. He pioneered the ethical sourcing movement in North America and is also the only certified Fairtrade Gold jeweler in the United States. Reflective Jewelry was named Santa Fe New Mexico’s Green Business of the Year in 2019, and he has been honored with several awards for his efforts to support ethical jewelry. His ebook, Ethical Jewelry Exposé: Lies, Damn Lies and Conflict Free Diamonds, is available online. Marc can be reached by email at marc(at)reflectivejewelry.com.